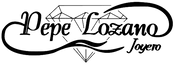

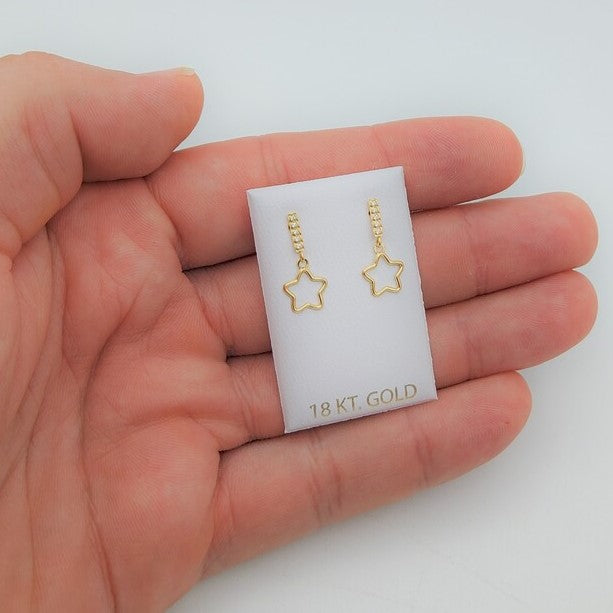

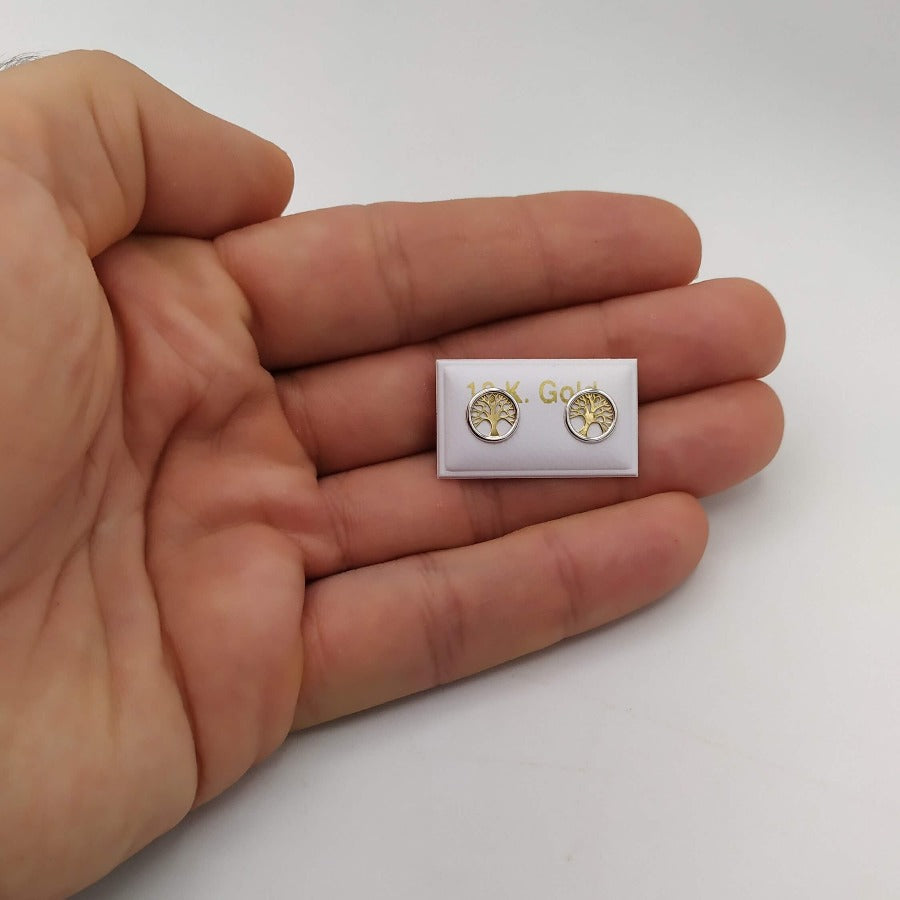

Pendientes de Oro

Comprar Pendientes de Oro 18K

Conoce nuestras diferentes categorías

Comprar Pendientes de Oro

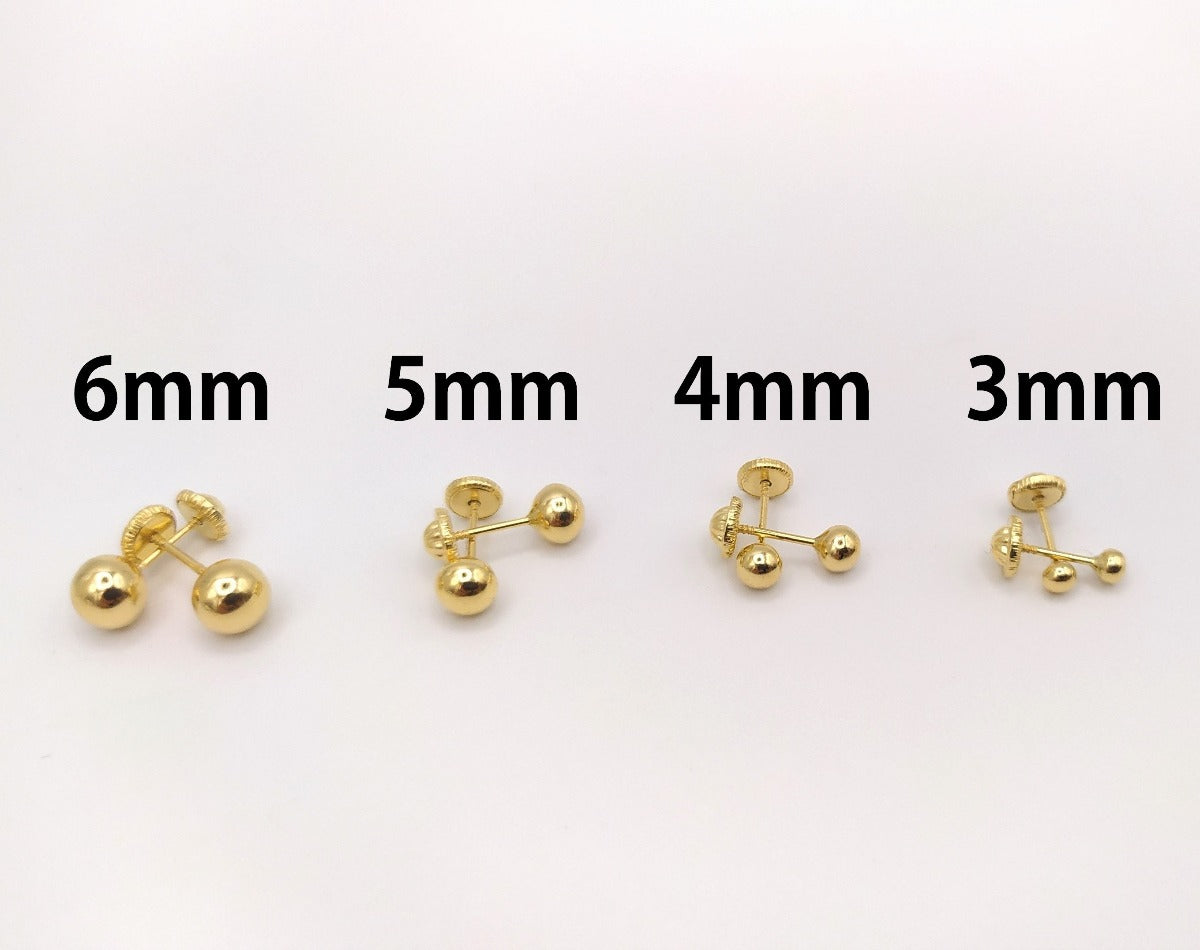

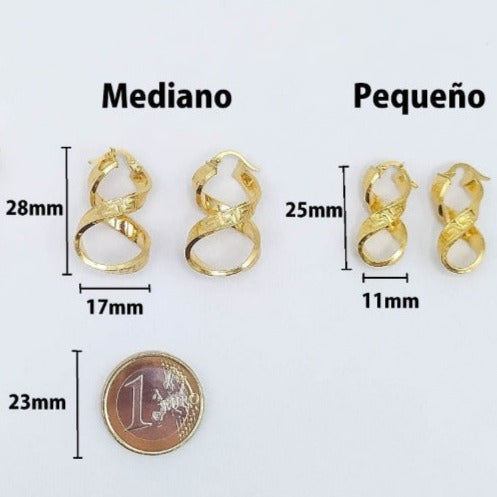

Amplia variedad de Pendientes de Oro para Hombre y Mujer

Pendientes de Oro 18k

Encuentra Tus Pendientes Amatista de Oro perfectos

Explora la Elegancia de los Pendientes de Oro Mujer en Nuestra Colección

VersaDrive ImpactaTap - Long Series

- 308015 ImpactaTaps are recommended for through hole applications only.

- Pilot drill the exact tapping size hole for best results

- Select the correct torque power for impact wrench/drivers using the data range in the Torque / RPM guide below. If exact match is not available select the closest torque setting above the recommendation.

- Apply firm, steady feed pressure throughout the cut

- Ensure the Tap is inserted squarely to the hole - poorly aligned or off-centre taps will greatly increase the risk of breakage.

- When using cordless tools, consider that the torque may drop once the battery charge becomes low. Keep batteries well charged. Low battery charge can lead to lower torque which can break or damage taps as point 3.

- Ensure regular application of quality cooling lubricant, especially when drilling thick or hardened materials.

- Hardened or heat-affected materials may require higher torque, reduced RPM and feed rates and extra coolant

- Flame cut/punched holes will require more torque to tap than drilled holes due to heat build up. Caution: Sometimes flame cut holes do not have parallel sides meaning risk of tap breakage.

- Tap the hole in one pass where possible, applying adequate lubrication before you start.

- If the tap is over-run from the hole once it is tapped, to remove the risk of cross-threading/damage to the tap, remove the tap from the adapter and locate it in the thread by hand, before reversing.

- When re-threading an existing thread, use caution to avoid cross-threading which can lead to tap breakage or thread damage. It is advisable to insert/start the tap into the thread by hand before driving it through at the correct torque

Use the tables below to identify the recommended Nm of Torque or RPM for your hole size and material.

Use Nm of Torque for tapping with Impact tooling.

Use RPM for tapping with Rotary tooling.

N.B. Impact Torque recommendations are the minimum required and for most applications additional torque is a benefit. For Impact applications where Torque values available do not offer an exact match to the table below select the closest available torque setting ABOVE the recommendation.

VersaDrive tooling can be used with a wide range of adapters that allow the products to be used across a variety of drive tools depending on the application required.

Below you will find the recommended adapters for the VersaDrive 308015 Long Series ImpactaTap.

- Identify the torque range (for the cutting tool) required using the data sheet in question 2. (Example M12 in 12mm plate – Guide torque 320Nm)

- Identify the torque range on your impact wrench or impact driver

- Look up model number to see torque range

- Check if there are speed/torque settings on the tool - Example

- Select the closest torque setting on the impact wrench/impact driver ABOVE the torque recommendation

(this is for the following 2 reasons)

- Higher torque will only be used on demand

- Too low torque will lead to the tool jamming or even snapping as the flutes stop cutting and the torque transfers to the tool

How to load a ImpactaTap into an Impact Driver adapter

Using a ImpactaTaps on medium thickness Stainless Steel

Using a M24 ImpactaTap on 25mm thick S275 Structural Steel

How to use an ImpactaTap with a standard Magnet Drill

How to use an ImpactaTap with a VersaDrive Magnet Drill & 111035 Rapid Lock Adapter

How to use an M6 ImpactaTap in a Pistol Drill Chuck

How to prevent cross threading if you over-tap the threads

How to use an ImpactaTap in a Hand Tapping Wrench

How to use an ImpactaTap with a hand ratchet (for blind or through hole tapping)